Chef’s Overview

Dear Chefs, have you ever stumbled across “HRC 60” or “Rockwell Hardness 59+” in a knife description and thought, “Well, that sounds official…but what does it mean?” You’re not alone. Rockwell Hardness is the universal language of steel toughness, but most brands never explain it clearly. Today, I’ll break down exactly what Rockwell Hardness is, why it matters for your kitchen knives, and how Pro Chefly forges blades in that sweet spot where sharpness meets durability.

What Rockwell Hardness Actually Measures

The Rockwell Hardness test measures how resistant steel is to indentation, which translates to how strong (and sharp) your knife can be. As we explained in What is the Rockwell Hardness Scale for Kitchen Knives, a harder steel means a sharper edge that lasts longer — but with great hardness comes great responsibility (and sometimes brittleness).

How the Test Works (Without the Science Lecture)

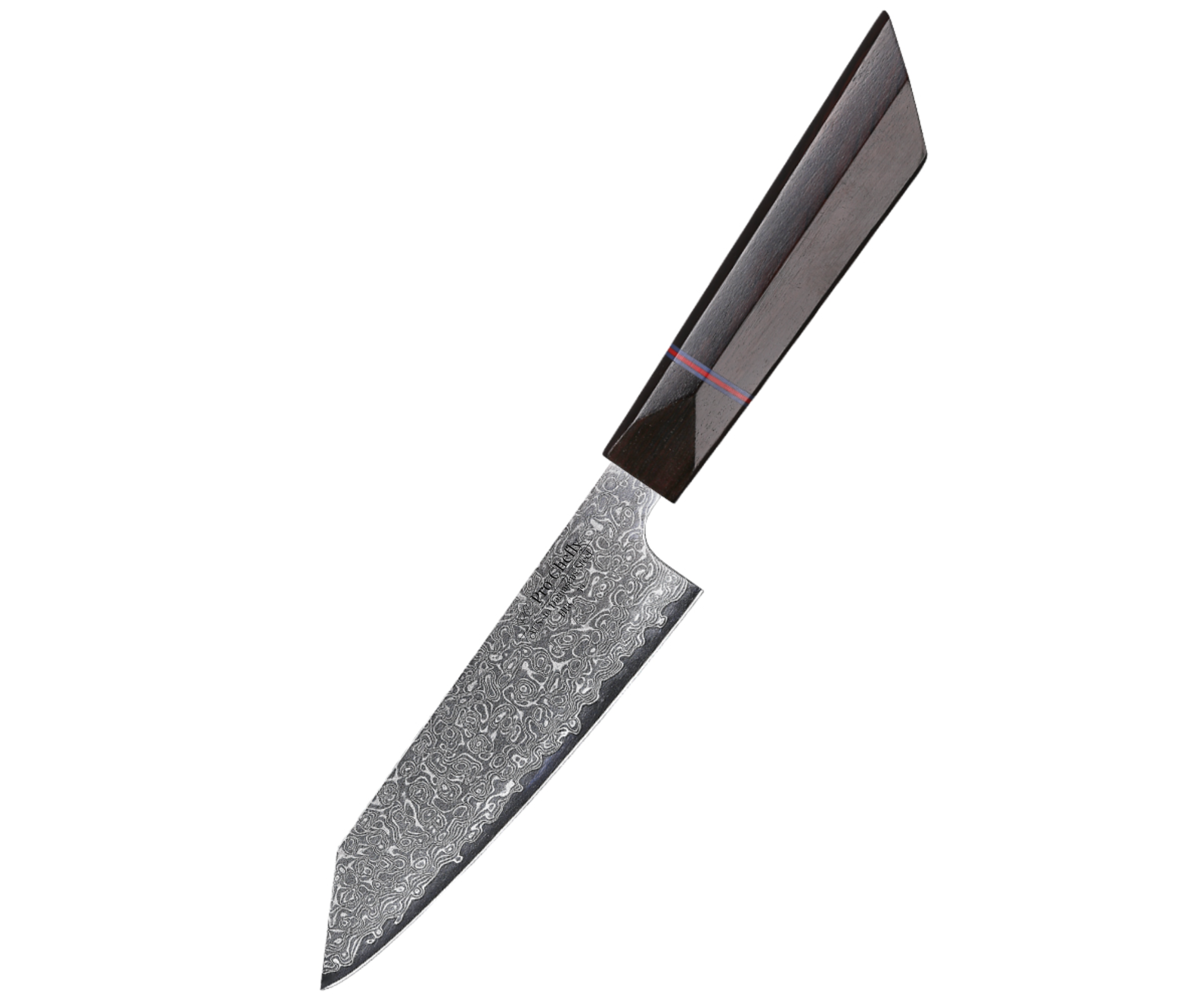

Imagine pressing a diamond-tipped tool into the steel. The deeper it sinks, the softer the steel. The shallower it goes, the harder the blade. The result is scored as “HRC.” A kitchen knife at HRC 59–61 (like our 8" VG-10 Damascus Chef Knife) strikes the perfect balance of edge retention and resilience.

Knife Hardness Ranges You’ll See in Kitchens

Not all knives are created equal, and Rockwell ratings tell the real story.

Softer Steels: Everyday Workhorses (52–57 HRC)

Affordable stainless steels often land here. They’re durable but dull quickly, so you’ll sharpen more often. Great for mass-market knives, not ideal for precision.

The Sweet Spot: Professional Japanese Standards (58–61 HRC)

This is where Pro Chefly lives. Steels like VG-10 and AUS-10 are hardened into this range, as we explored in How Does VG-10 Compare to AUS-10 and Other Premium Steels. Knives like the 7" AUS-10 Damascus Santoku Knife and 5" VG-10 Damascus Petty Knife give chefs razor-sharp edges with resilience for daily cooking.

Extra Hard: Specialist Blades (62+ HRC)

Blades this hard can take an insanely fine edge but risk chipping if misused. As we noted in Is Damascus Steel Stronger Than Other Kitchen Knife Steels, strength isn’t just hardness — it’s balance. That’s why most chefs stick to the sweet spot.

Why Rockwell Hardness Matters in Everyday Cooking

Here’s the thing: hardness isn’t just a number for steel nerds. It’s about how your knife feels when you cook. A softer knife might make you feel like you’re sawing through an onion. A harder Damascus blade, like the 8.5" VG-10 Damascus Kiritsuke Knife, glides cleanly and stays sharp longer — making prep work faster, easier, and more enjoyable.

Choosing the Right Knife for the Task

-

Need all-purpose versatility? The 8" VG-10 Damascus Chef Knife at 60 HRC is your kitchen anchor.

-

Want vegetable precision? The 7" VG-10 Damascus Nakiri Knife keeps straight edges sharp for clean cuts.

-

Love compact control? The 5" AUS-10 Damascus Mini Bunka Knife balances sharpness and toughness beautifully.

Bringing It All Together

Dear Chefs, Rockwell Hardness may sound technical, but really it’s just a guide to confidence. Too soft, and you’ll sharpen endlessly. Too hard, and you’ll worry about chips. But land in that Pro Chefly zone of 59–61 HRC, and your knife becomes more than steel — it becomes a trusted companion that sharpens your cooking and your joy. Now, when you see “Rockwell Hardness” on a blade, you’ll know it’s not just a number. It’s the secret to making every cut feel effortless.

Knife Collections

Shop the latest in Pro Chefly Damascus Knives

Chef's Notes

Stay up to date with the latest kitchen stories and recipes

- December 05, 2025

Dear Chefs, the holidays deserve a dish that feels slow, soulful, and unforgettable — and few things capture that spirit...

- November 30, 2025

Dear Chefs, there is something unmistakably comforting about bread pudding in November — the way the custard soaks into the...

- November 25, 2025

Dear Chefs, there is something special about roasted carrots in the fall — the way they caramelize, the way their...

- November 20, 2025

Dear Chefs, there is something magical about fall stuffing, especially when pumpkin and sage join the party. The aroma alone...

- November 15, 2025

Dear Chefs, November has a rhythm of its own — a slower pace, a softer light, and a craving for...

- October 31, 2025

Dear Chefs, fall baking is a ritual — the scent of cinnamon in the air, pecans roasting low and slow,...

- Choosing a selection results in a full page refresh.

- Opens in a new window.