Chef’s Overview

Dear Chefs, let’s talk about a number that holds more weight in your kitchen than you think: Rockwell Hardness. This little measurement (HRC) decides how sharp your knife can get, how long it stays that way, and how much maintenance it needs. In this story, we’ll break down how hardness impacts sharpness and edge retention — and why finding the right balance is what turns a blade into your best kitchen companion.

Rockwell Hardness: The Backbone of Sharpness

Hardness is measured on the Rockwell scale, and as we explored in What is the Rockwell Hardness Scale for Kitchen Knives, it tells us how resistant the steel is to wear. A higher number means harder steel, which generally allows a knife to take on a finer, sharper edge. That’s why Japanese steels like VG-10 and AUS-10 — the stars of Pro Chefly knives — are celebrated worldwide.

Why Harder Steels Stay Sharper

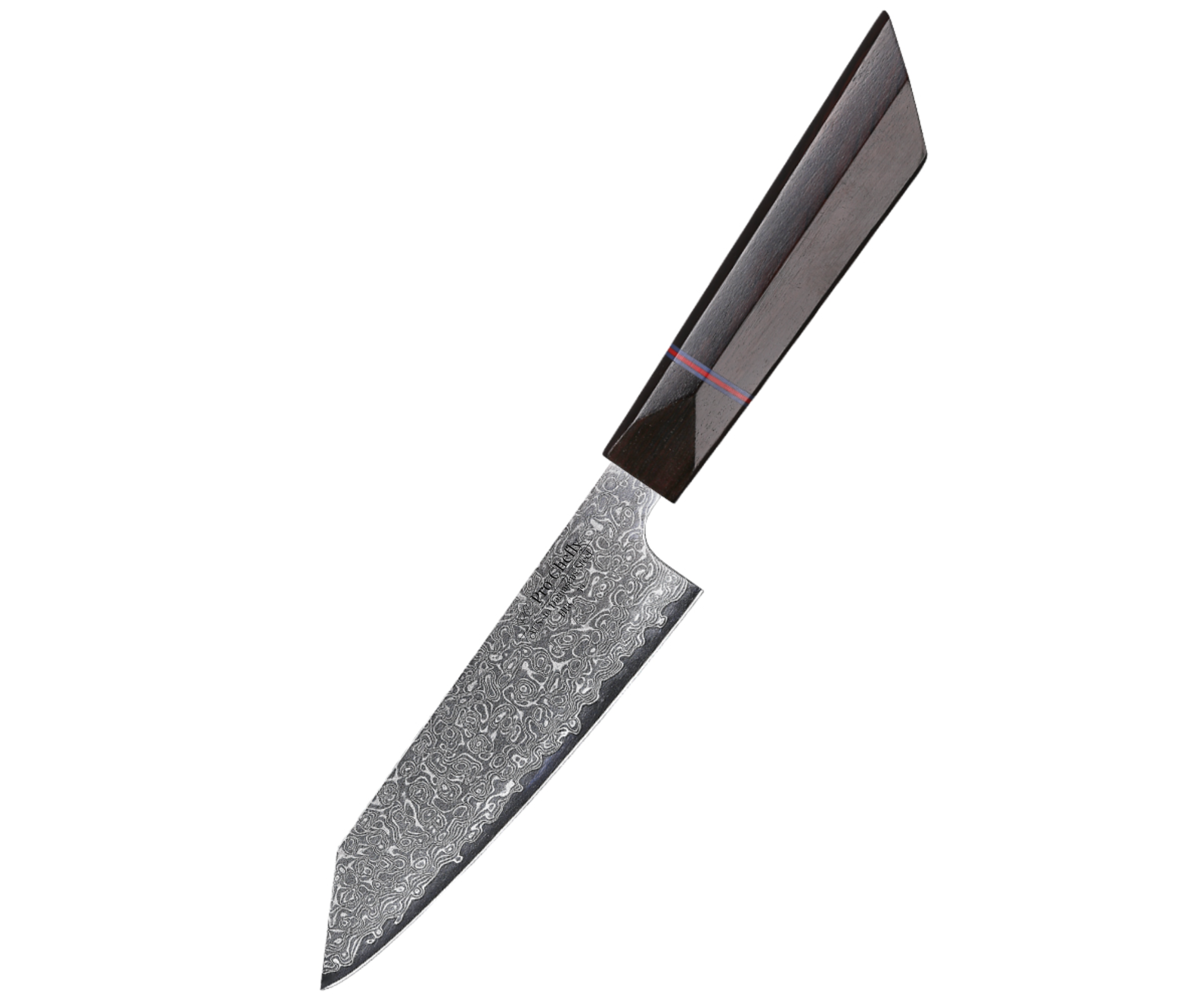

A blade hardened to 60+ HRC, like the 8" VG-10 Damascus Chef Knife, can be honed to an incredibly fine edge and keep that sharpness longer than softer steels. Less rolling, less dulling, more glide through tomatoes, herbs, and proteins.

The Catch: Too Hard Can Chip

As we mentioned in Is Damascus Steel Stronger Than Other Kitchen Knife Steels, hardness is a balancing act. Push steel too far (63+ HRC), and while you gain sharpness, you lose resilience. That’s when edges chip instead of flexing.

Edge Retention: How Long Your Knife Stays Sharp

Sharpness is the thrill, but edge retention is the marathon. Harder steels naturally hold an edge longer because they resist deformation. But here’s the twist: edge retention isn’t just hardness, it’s also about heat treatment, forging, and the steel blend. That’s why we love VG-10 and AUS-10 cores layered in Damascus. They offer a “best of both worlds” approach — long edge life without fragility.

Comparing Edge Life Across Steels

-

Soft Stainless (54–57 HRC): Easy to sharpen, dulls quickly, best for budget or heavy-use knives.

-

Balanced Zone (58–60 HRC): Where knives like the 7" AUS-10 Damascus Santoku Knife thrive. Great sharpness with forgiving resilience.

-

Harder Zone (60–62 HRC): Knives like the 8.5" VG-10 Damascus Kiritsuke Knife shine here. Serious sharpness and long retention, perfect for chefs who value performance.

Why Pro Chefly Chooses the Sweet Spot

At Pro Chefly, we’re not chasing the hardest steel possible — we’re chasing the best experience in your hand. Hardness matters, but so does the joy of using your knife daily. That’s why we forge most of our blades between 59–61 HRC. It’s the range that gives you razor-sharp performance, strong edge retention, and just enough toughness to handle everyday cooking without stress. As we highlighted in How Does VG-10 Compare to AUS-10 and Other Premium Steels, these steels deliver consistent results where it counts most: your cutting board.

The Everyday Impact in Your Kitchen

Think about chiffonading basil with the 5" VG-10 Damascus Petty Knife or dicing onions with the 7" VG-10 Damascus Nakiri Knife. Both are hardened to that sweet spot, meaning they stay sharp longer and need fewer touch-ups. Less time at the sharpening stone, more time enjoying the flavors you’re creating.

The Sharpest Balance for Everyday Chefs

Dear Chefs, hardness gives us sharpness, but balance gives us joy. Too soft and you’re sharpening endlessly. Too hard and you’re stressing over chips. But land in the middle — around 59–61 HRC — and you’ve got blades that stay sharp, perform beautifully, and let you focus on cooking, not maintenance. At Pro Chefly, that’s the balance we forge into every knife. Because sharpness isn’t just about numbers — it’s about confidence, control, and a little magic in your hands.

Knife Collections

Shop the latest in Pro Chefly Damascus Knives

Chef's Notes

Stay up to date with the latest kitchen stories and recipes

- December 05, 2025

Dear Chefs, the holidays deserve a dish that feels slow, soulful, and unforgettable — and few things capture that spirit...

- November 30, 2025

Dear Chefs, there is something unmistakably comforting about bread pudding in November — the way the custard soaks into the...

- November 25, 2025

Dear Chefs, there is something special about roasted carrots in the fall — the way they caramelize, the way their...

- November 20, 2025

Dear Chefs, there is something magical about fall stuffing, especially when pumpkin and sage join the party. The aroma alone...

- November 15, 2025

Dear Chefs, November has a rhythm of its own — a slower pace, a softer light, and a craving for...

- October 31, 2025

Dear Chefs, fall baking is a ritual — the scent of cinnamon in the air, pecans roasting low and slow,...

- Choosing a selection results in a full page refresh.

- Opens in a new window.