Chef’s Overview

Dear Chefs, let’s get sharp about something most people overlook: Rockwell Hardness. You’ve probably seen numbers like 58 HRC, 60 HRC, or 62 HRC tossed around in knife descriptions, but what do they actually mean for your cooking? In this story, we’ll slice through the jargon, explain what makes an ideal hardness score for chef knives, and show you why the right balance is the secret to performance, durability, and joy in the kitchen.

The Rockwell Scale Explained: Measuring Knife Hardness

The Rockwell Hardness Scale (HRC) is the kitchen world’s version of a report card for steel. It measures how resistant the steel is to indentation, which translates into how long your knife will stay sharp before needing a touch-up. As we explored in What is the Rockwell Hardness Scale for Kitchen Knives, the higher the score, the harder the steel — but harder doesn’t always mean better. Too hard, and your knife risks chipping. Too soft, and it won’t hold an edge for long.

The Sweet Spot for Kitchen Knives

For most chef knives, the best Rockwell hardness rating falls between 58 and 62 HRC. This range offers an excellent compromise between durability and edge retention. Japanese steels like VG-10 and AUS-10 are prized because they land right in this sweet spot — hard enough for razor sharpness, yet forgiving enough for daily use.

Comparing Hardness Levels in Chef Knives

Different steels behave differently depending on their HRC rating, and that’s why choosing the right blade is essential.

Softer Steels (54–57 HRC)

These steels are durable but dull quickly. You’ll find them in budget kitchen knives that can handle rough treatment but require constant sharpening.

The Balanced Zone (58–60 HRC)

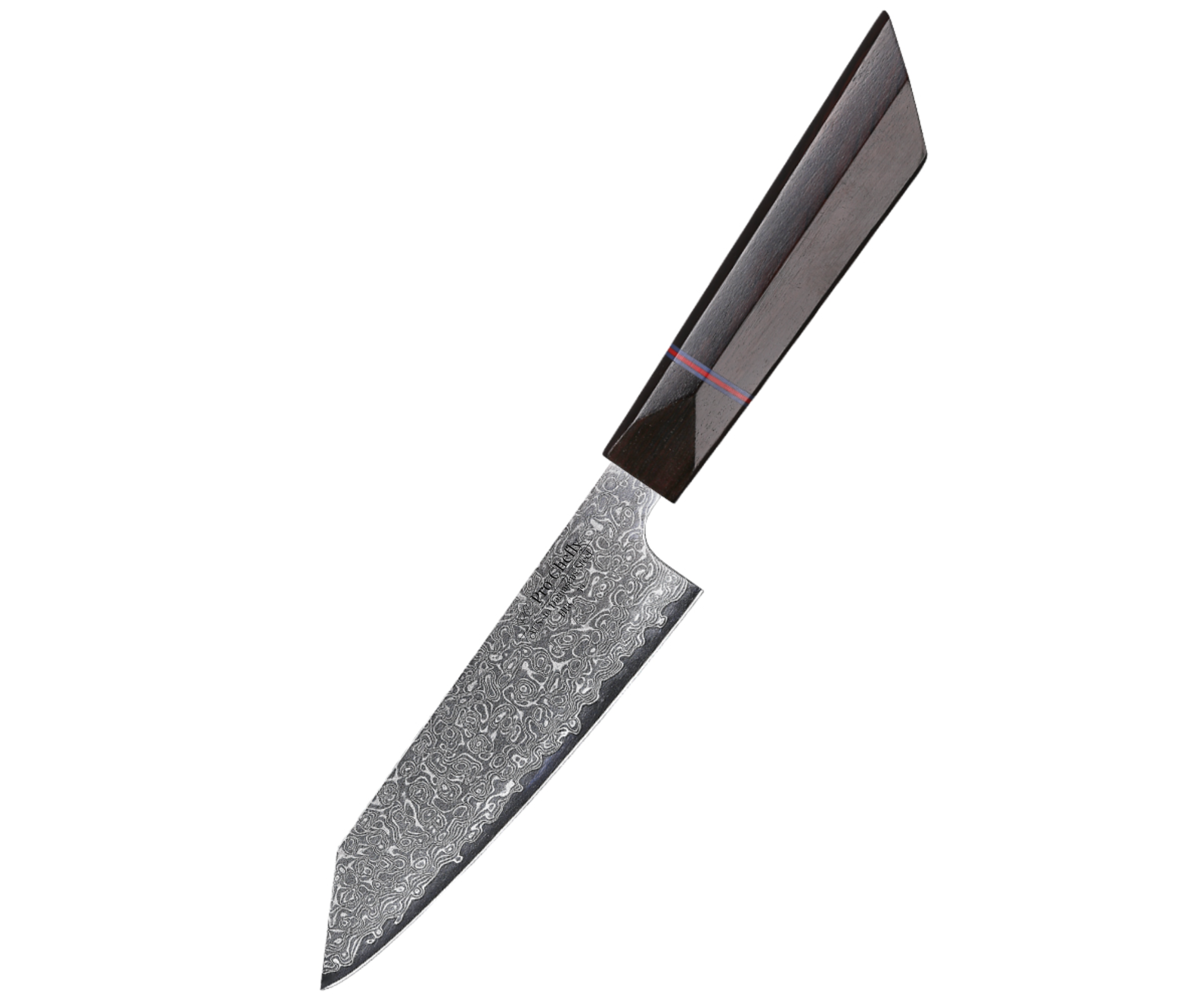

This is where many Pro Chefly knives live. For example, the 8" VG-10 Damascus Chef Knife and 7" VG-10 Damascus Santoku Knife both feature steel hardened around 60 HRC. That means they hold an edge for longer while staying resilient enough to withstand daily prep.

Harder Steels (61–63 HRC and above)

At this range, you get unmatched sharpness and edge retention. Knives like the 8.5" VG-10 Damascus Kiritsuke Knife thrive here. But remember — with great sharpness comes greater responsibility. Harder knives require careful use and proper care to prevent chips.

Why Pro Chefly Balances Sharpness and Strength

At Pro Chefly, we design our knives to fit the lifestyle of real chefs and passionate home cooks. That’s why we love steels like VG-10 and AUS-10. As we discussed in How Does VG-10 Compare to AUS-10 and Other Premium Steels, these steels balance sharpness, durability, and stain resistance in ways softer steels can’t. And unlike overly brittle blades, ours are built to handle everything from a delicate tomato slice to a firm chop through root vegetables.

Everyday Performance in the Kitchen

Think of Rockwell hardness like seasoning. Too little, and the dish falls flat. Too much, and it overwhelms. But just the right amount? Perfection. With knives like the 5" AUS-10 Damascus Petty Knife and the 7" AUS-10 Damascus Santoku Knife, you’ll feel how that balance translates into smooth cuts, fewer sharpenings, and more fun in the kitchen.

Choosing the Best Rockwell Hardness for You

So, what’s the magic number? For most chefs and home cooks, the sweet spot lies between 58 and 62 HRC. It’s where knives stay razor-sharp without being fragile, and where maintenance becomes manageable rather than a chore. Anything softer, and you’ll be sharpening constantly. Anything harder, and you’ll need to baby your blade. That’s why Pro Chefly knives are forged right in this golden zone — to give you confidence and consistency in every cut.

Wrap-Up: Hardness That Fits Your Cooking Style

Dear Chefs, the “best” Rockwell hardness rating isn’t about chasing the highest number. It’s about balance — sharp enough to impress, durable enough to last, and forgiving enough to make cooking enjoyable. That’s why we forge our knives where sharpness meets strength. So next time you see that little HRC number, remember: it’s not just science, it’s the recipe for a knife you’ll love using every single day.

Knife Collections

Shop the latest in Pro Chefly Damascus Knives

Chef's Notes

Stay up to date with the latest kitchen stories and recipes

- December 05, 2025

Dear Chefs, the holidays deserve a dish that feels slow, soulful, and unforgettable — and few things capture that spirit...

- November 30, 2025

Dear Chefs, there is something unmistakably comforting about bread pudding in November — the way the custard soaks into the...

- November 25, 2025

Dear Chefs, there is something special about roasted carrots in the fall — the way they caramelize, the way their...

- November 20, 2025

Dear Chefs, there is something magical about fall stuffing, especially when pumpkin and sage join the party. The aroma alone...

- November 15, 2025

Dear Chefs, November has a rhythm of its own — a slower pace, a softer light, and a craving for...

- October 31, 2025

Dear Chefs, fall baking is a ritual — the scent of cinnamon in the air, pecans roasting low and slow,...

- Choosing a selection results in a full page refresh.

- Opens in a new window.